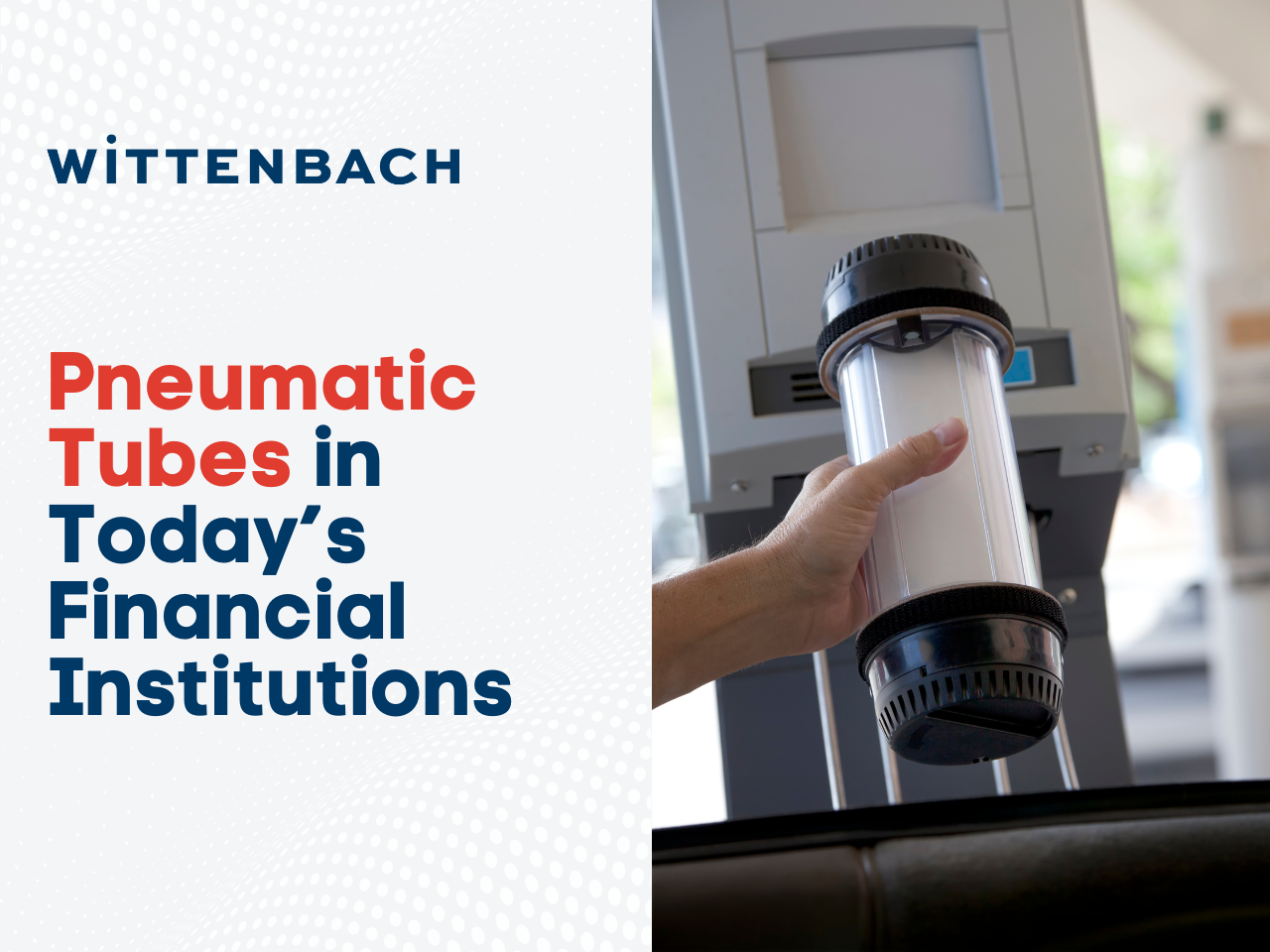

Pneumatic tube systems are an ongoing component of the in-person transaction experience at financial institutions, transferring money and documents between drive-through clients and tellers. Even in the digital age, this technology continues to serve as a behind-the-scenes means of moving goods and information. At Wittenbach, we safely install, maintain, and repair these tube systems with seasoned expertise across industries. We are partners with manufacturer Hamilton Security, who designs tube systems not only for the financial sector, but in virtually any setting in which a quick exchange of documents, money, or small goods ensures timely and smooth operations.

How does a pneumatic tube system work?

In its basic form, a pneumatic tube system “is technical equipment in which cylindrical containers (carriers) are propelled through a complex network of tubes by compressed air or by vacuum. They are used for transporting physical objects.” This kind of object transportation system is used in numerous industries: in hospitals, it may transport tests and samples; in pharmacies, classifying and transporting various medications; in office buildings, perhaps moving the mail; and in retail settings, it may transfer cash to a safe. In the financial sector, banks and credit unions use pneumatic tube systems to efficiently transport cash and documents between a drive-through customer outside, and a teller inside the branch building.

This compressed-air system is not new; it rose in popularity in the late 19th century primarily as a mail delivery mechanism. Now, although not a novel innovation, it remains a reliable and quick means of transporting items over short distances. As financial institutions continue to recognize the relevance of physical branches, the use of pneumatic tube systems also remains relevant.

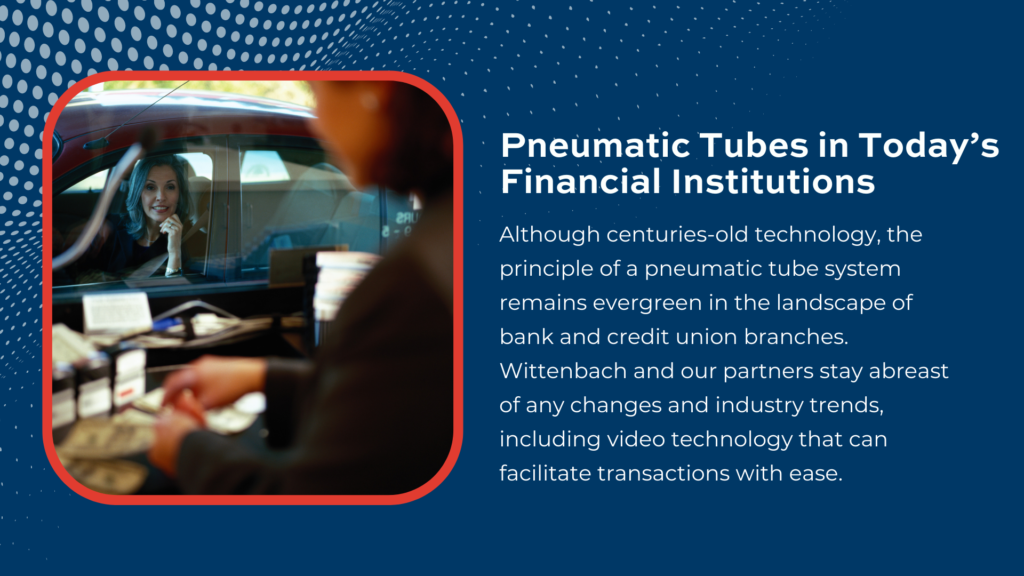

In the most common tube systems at financial institutions, the model consists of a teller unit and a customer unit. These are connected by a 4.5-inch-wide tubing that uses a blower to carry a canister back and forth, from one end to the other. Wittenbach expert Scott McDade explains, “The pneumatic tube system is a pretty simple design. The only advancement in the past few years would be adding two-way video systems that make it easier for customers to see tellers, and vice-versa.” The Hamilton HA1000-XLR is one model that embraces these innovations, with its two-way video system and high-quality microphone and camera that ensures your branch’s clients are seen and heard. Ideal for new construction and replacement projects, the HA1000-XLR is sleek, weatherproof, and antimicrobial.

In addition to selling new pneumatic tube systems, Wittenbach is also well-versed in the installation, maintenance, and removal of these models. Our experts have seen it all and know how to troubleshoot blockages, plan for building renovations, and optimize the use of your existing systems. Wittenbach also sells the right accessories needed to run a pneumatic tube system, such as drive-through carriers, approved coin and cash wrappers, and cleaning supplies.

Common pneumatic tube system issues resolved

- Mechanical issues: MC Hydraulics outlines the most common mechanical malfunctions that arise in pneumatic tube systems. The first is a damaged or dirty filter, which can be remedied by cleaning and changing it regularly. Air seal leaks can cause the tube system to move slowly or even cause “cylinder drift”, meaning the actuator shifts and the pressure is unbalanced. An ultrasonic acoustic detector can be used to prevent this as well. Another common issue is the directional control valve not functioning as expected: “Dirt or debris in the system can cause the valve to stick and not change direction as it should. Regular cleaning and replacement of the filter will help to prevent this problem before it surfaces. The valve itself may need cleaning or replacing.” Wittenbach’s experts also note, “Often, we’re also looking into a blower/motor turbine issue, a control board, or a relay switch.” Proper maintenance and monitoring can help to avoid nearly all of these issues.

- Upsend vs downsend: McDade explains further, “This simply refers to the direction the carrier travels with leaving the customer or teller unit. The upsend will travel up through the ceiling whereas the downsend will travel down underground.” Common issues with downsend include blockages from mud or water, as well as heavy coins getting stuck in an underground tube. Wittenbach recommends the use of upsend, since downsend presents these subterranean issues; however, we can help your branch troubleshoot either configuration.

- Minding weight limits: It is important not to overload your pneumatic tube system, in order to prevent blockages and damage to the unit. Most systems used in financial institutions, such as Hamilton’s HA1000-XLR, have a limit of approximately 5-7 pounds. This means that they can transport items efficiently, but should not be filled with rolls of coins or other heavy items. Other commercial units, such as the HA-47 or the HA-33 offer larger payload capacities.

- Preventive maintenance: Provider Valmet offers a maintenance schedule that can ensure systems are running smoothly. They suggest on a weekly basis to drain air line filters and check water traps. Monthly, they advise to check for air leaks, to add lubricant to mist lubricators, and externally clean components and actuators. Every six months, air filters should also be replaced. Other tasks, such as lubricating cylinders and pivot points, as well as replacing silencers, are recommended on an as-needed basis.

Conclusion

Although centuries-old technology, the principle of a pneumatic tube system remains evergreen in the landscape of bank and credit union branches. Wittenbach and our partners stay abreast of any changes and industry trends, including video technology that can facilitate transactions with ease. In addition, we understand the importance of your investment, and can help you to maintain and service your pneumatic tube system. If you’re seeking advice with an existing tube system, an installation, or a removal, don’t hesitate to contact Wittenbach today; our experts will gladly answer your questions!